Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: GOC10-150

Usage: Oxygen

Application Fields: Medical

Certification: ISO

Type: Diaphragm

Packaging: Plywood box

Transportation: Ocean,Land

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT

Wind or Water Cooling Oxygen Booster Compressor

Safety valve is installed on the first stage cooler, whose starting pressure is 4.0MPa (It has set before leaving factory). Second stage safety valve`s starting pressure is 16.5MPa (This valve should be provided by user.). Safety valves should be check by professional measurement department and arbitrary unsealing is forbidden.

Oil discharge pressure checking mechanism of oil cylinder is composed of vibrate bearing pressure meter, damper and non-return valve. The shell of vibrate bearing pressure meter is sealed off by damp liquid and all the inside mechanism is sink in damp liquid, which can keep the meter needle`s stability for the glutinosity of damp liquid. The damper installed under vibrate bearing pressure meter is adjustable. It can be adjusted according to the pulsating range of measured oil pressure. Properly changing the depth the needle valve can reduce the instantaneous strike on oil pressure meter caused pulse of oil pressure and prolong the life of oil pressure meter. Because of the damper`s pressure loss, the measured oil pressure will be lower than actual value. In order to reduce measurement error, with the condition of minimum descend of pressure, it`d better to maintain slightest swing and lowest ascending speed of needle of oil pressure meter. Deflating needle valve is installed under damper, which is used to exel the remained air and unload for oil pressure meter. Non-return valve is installed under deflating needle valve, which connects with oil cylinder through pipes.

Performance Characteristics

| Working principle | Oil-free lubrication reciprocating type |

| Cooling type | Wind or water cooling |

| Power consumption | Not more than 110 KW |

| RPM range | 300-600rpm |

| Capacity range | 1-200Nm3/h |

| Inlet pressure: | 0.05-10bar |

| Outlet pressure | 150bar |

| Compressed grade | 1-4 |

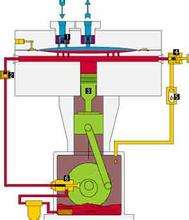

This oxygen booster compressor use the technology of diaphragm, the oxygen compression is realized by the compression of diaphragm, the oxygen does not touch with piston,etc, therefore there is no lubricant oil touching with oxygen, ensure oxygen not be polluted. This kind of Oxygen Compressor is suitable for increasing oxygen for medical usage, which require extreme clean oxygen.

Oxygen Compressor Process Introduction

Diaphragm Compressor is mainly composed of [V-style" first and second stage cylinders, crank box, crank connecting pole structure, bottom, cooling system and so on.

Product Categories : Gas Compressor > Oxygen Compressor

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.