Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Gamma Gas

Usage: Nitrogen

Purpose: Gas separation

Application Fields: Petroleum

Noise Level: Low

Machine Size: Medium

Condition: New

Certification: CE

Technology: PSA Pressure Swing Adsorption

Packaging: Plywood packing

Productivity: 20 PCS per month

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: CE certification

HS Code: 84213990

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Gamma Easy Operation Automatic Food Packing Nitrogen Generator is based on Pressure Swing Adsorption(PSA) technology. It can reach purity 90-99.9999%, flow rate 1-3200 Nm3/hr, outlet pressure 1-150 bars. It is widely used in fields such as Food and beverage industries, Analytical chemistry,Aircraft & motor vehicle tires,Chemical and petrochemical industries,Electronics,Glass industry,Metallurgy,Paint-and-varnish industry,Petroleum industry,Pharmaceutical industry,Hypoxic air fire prevention system

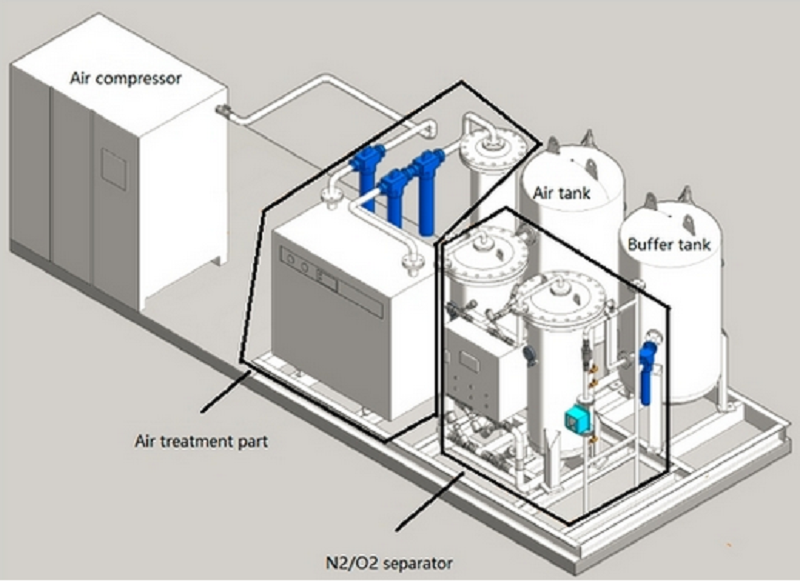

Gamma Easy Operation Automatic Food Packing Nitrogen Generator consists of several parts. They are air compresosr, air treatment part, air tank, nitrogen separator and nitrogen buffer tank. It has features of intelligent control, fully automatic operation,etc. It is the ideal replacement of cylinder nitrogen supply or liquid nitrogen supply.

Pressure swing adsorption processes rely on the fact that under pressure, gases tend to be attracted to solid surfaces, or "adsorbed". The higher the pressure, the more gas is adsorbed; when the pressure is reduced, the gas is released, or desorbed.

Easy Operation Automatic Food Packing Nitrogen Generator Process Flow

Air Compressor suction air from atmosphere,then the compressed air enters one air treatment part to get rid of dust,water, dust,etc, achieving clean and dry compressed air. This air treatment part mainly consists of three filters, one Refrigerant Dryer and one activated carbon oil remover. After treatment, the compressed air enters one air tank to make air stable. Then the compressed air enters PSA nitrogen/oxygen separator. After passing through this nitrogen/oxygen separator part, nitrogen is collected. The produced nitrogen enters one nitrogen buffer tank. At the outlet of nitrogen buffer tank, stable and qualified nitrogen is sent to using point.

Easy Operation Automatic Food Packing Nitrogen Generator Specification

Flow rate: 10-4000 Nm3/hr

Purity: 90-99.9999%

Outlet perssure: 5-200 bars(72.5-2900 psi)

Easy Operation Automatic Food Packing Nitrogen Generator Structure

It consists of air compressor, air treatment part, air tank, nitrogen separator part and nitrogen buffer tank.

Here are some different flow machines for reference:

Product Categories : Skid Nitrogen Generator > Standard Nitrogen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.