Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Gamma Gas

Usage: Oxygen

Purpose: Gas Manufacturing

Application Fields: New Energy

Noise Level: Low

Machine Size: Medium

Condition: New

Certification: CE

Name: Factory 93% Purity Industrial Oxygen Generator

Packaging: Plywood wooden box

Productivity: 30 pcs per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 sets per month

Certificate: CE certificate

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

Factory 93% Purity Industrial Oxygen Generator is 93% purity Industrial Oxygen Generator, which is widely used in many applications. Combustion assistance is one of them. This machine etadapts PSA technology, produce oxygen from air.

93% purity industrial Oxygen Generator specification

| Item | Technical parameter | Remarks | |

| Model No. | POM93-90 | ||

|

Oxygen index | Purity | ≥93% |

|

| Ave flow | ≥90 Nm3/h | 20°C,101.325Kpa | |

| Pressure | ≥5 bars | Gauge pressure | |

| Dew point | ≤-40°C | Normal pressure | |

| Noise | ≤80 Db(A) | One meter from equipment | |

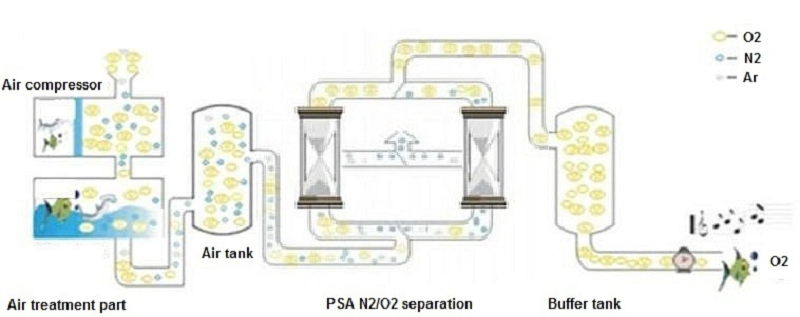

It use Air Compressor as raw material supplier, use three filters, one dryer and one oil remover to get rid of impurities from the compressed air . Then the treated air goes into one air tank to stablize pressure and flow rate. Then the compressed air enters one oxygen separator, this is the key part for oxygen equipment. After air pass through this part, high purity oxygen (93%) is collected. The collected air is sent to one buffer tank then send to industrial applications.

Industrial High Purity PSA Oxygen Equipment Features

Skid structure, easy installation.

When this industrial oxygen generator reaches site, just connect the air compressor into main machine, then with one simple touch on the start, the whole machine starts to work, no need for site installation, site training,etc. No need for Gamma engineers go to site, further saving customer`s cost.

Special filling device

Making the fill of molecular sieve achieve max density and evenness. Getting rid of molecular sieve creeping and wearing and [tunnel effect" from the root. Therefore the molecular sieve has longer lifetime, higher utility ratio and lower material air consumption.

Special gas distributors

Equipped at both top and bottom side of the adsorption tower

adapting multi-layer hole plate structure and special hole arrangement. These makes gas distribution within tower more efficient.

Pipeline flow speed control technology

Making the molecular sieve avoid damage caused by collision by [boiling" at the top of adsorption tower, no need extra pressing device.

Advanced middle bed layer pressure balancing process

Can be regarded as a four tower structure with series connection of pre-adsorption stage and clean adsorption stage, achieving higher purity oxygen.

93% purity industrial oxygen generator packing and shipping

After sales service

Free customer site installation guidance, free training for operation and maintenance. No need to pay for Gamma engineer's site service.

One years operation warranty. Should any trouble happened, Gamma provide and send parts free of charge. If necessary, Gamma engineer comes to site at our own cost.

Product Categories : Industrial Oxygen Generator > 93% Purity Industrial Oxygen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.